From Digital Mesh to Physical Object: Mastering 3D Printable Models

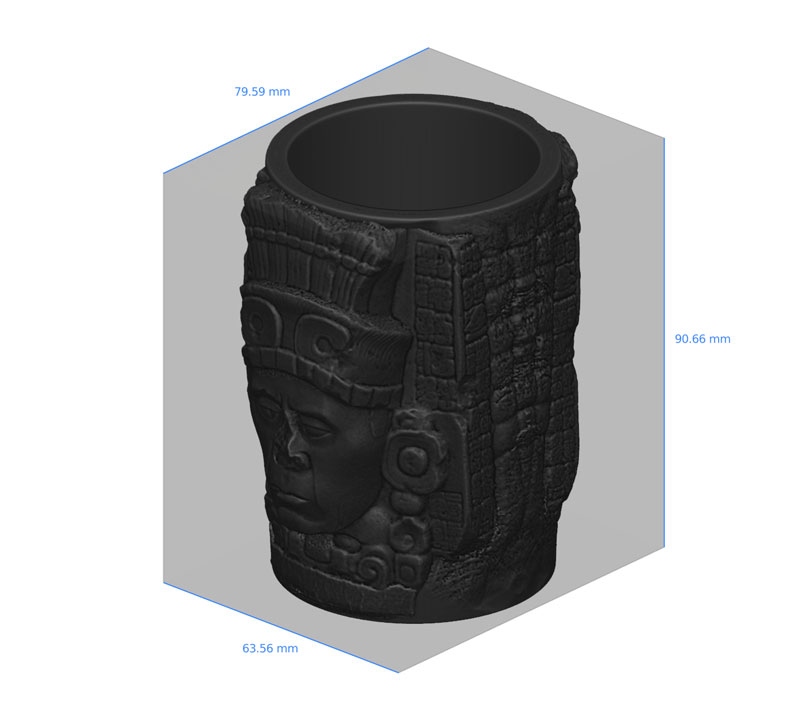

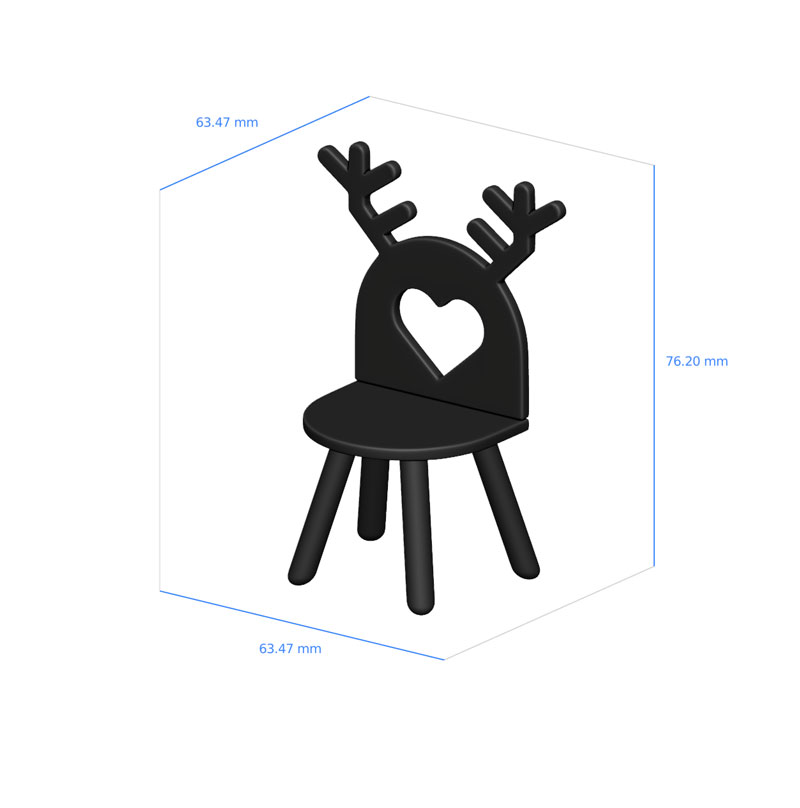

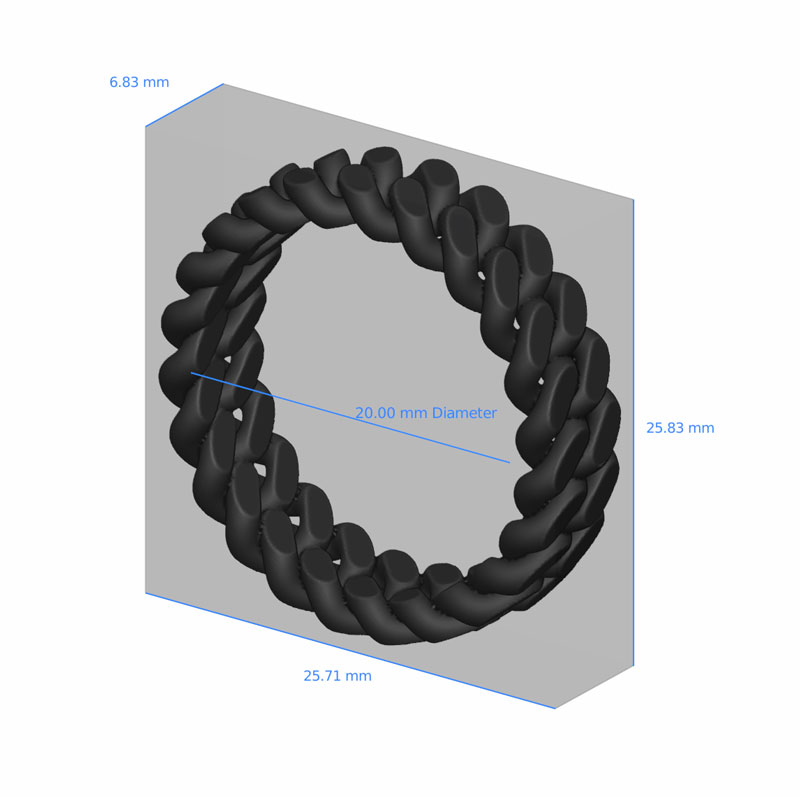

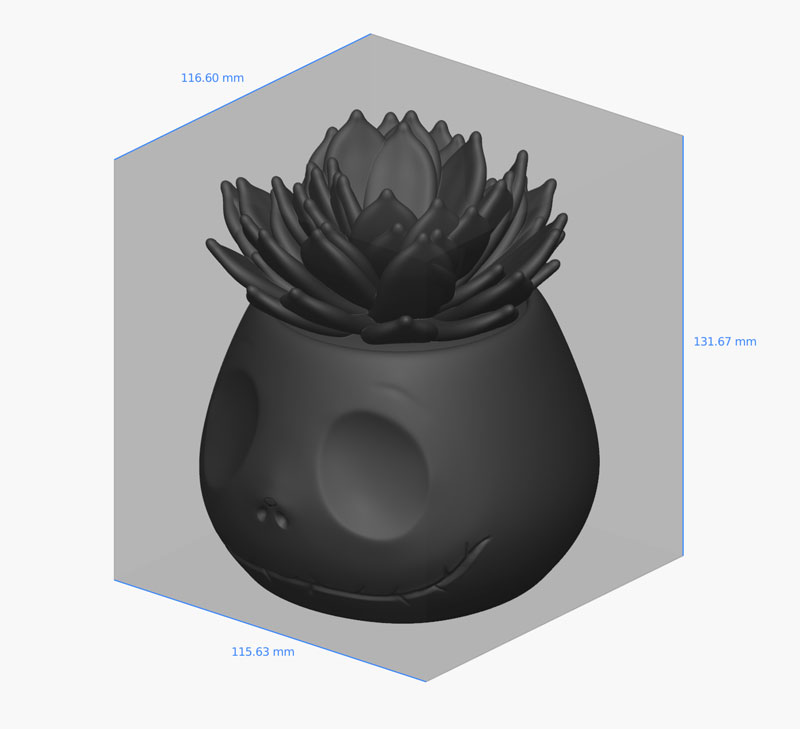

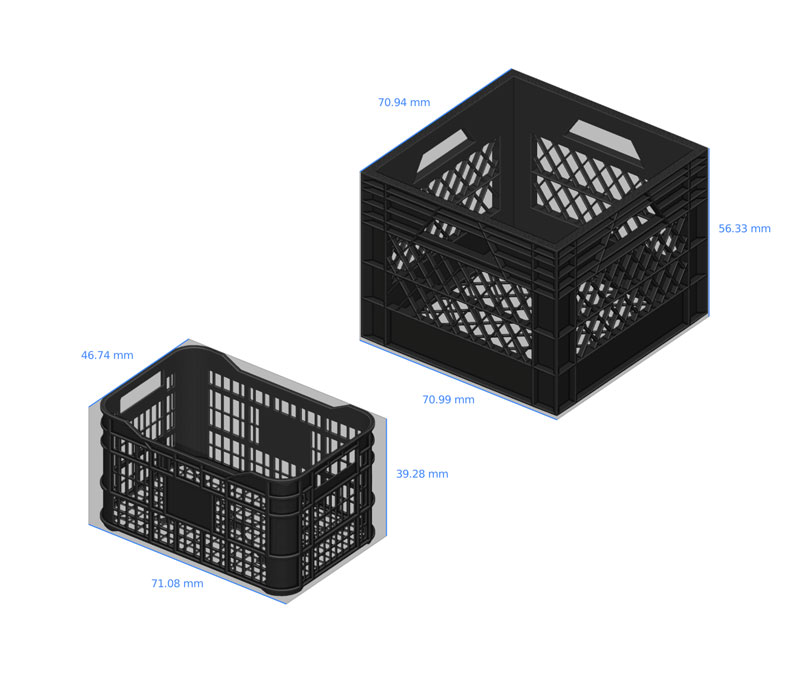

In the world of 3D Artist, creating a visually stunning model for a render is one challenge; creating a flawless, print-ready file for physical fabrication is an entirely different one. The Multiple 3D Models for Printing project is a testament to this distinction, showcasing a deep understanding of the technical demands required to bring a digital Concept to life. This comprehensive case study highlights our expertise in creating high-quality 3D Printable Models, perfectly suited for a wide range of applications from rapid prototyping and product development to custom art and manufacturing.

The Challenge: Creating Watertight and Manifold Models for a Flawless Print

A client, a product designer, sought a series of digital files that were guaranteed to be print-ready for their prototyping needs. The core task was multi-faceted and demanding.A non-manifold mesh, with its unsealed edges, internal faces, or duplicate geometry, is a recipe for print failure. The project required an artist who could see beyond the visual aesthetics and focus on the structural integrity required for physical output. The goal was to produce a collection of files that would save the client time and resources by eliminating the need for extensive pre-print cleanup and repair.

Our Solution: A Dedicated Workflow for Digital Fabrication in Blender

Leveraging the advanced capabilities of Blender, our team, with a skilled 3D artist from Mardan, Khyber Pakhtunkhwa, Pakistan, undertook a comprehensive approach to bring these 3D Models to life:

- Meticulous Hard-Surface Modelling: The project began with a focus on creating models with clean, efficient topology. Every object was built from the ground up with a solid structure in mind, using clean geometry to prevent errors from the outset. This foundational step is critical for a smooth transition from digital to physical form.

- The Manifold & Watertight Workflow: This was the most crucial part of the process. We utilized Blender’s specialized 3D Print Toolbox add-on to systematically check and repair each model. This robust workflow included:

- Checking for Non-Manifold Geometry: We meticulously scanned for edges that were not connected to exactly two faces, ensuring the model was a single, cohesive volume.

- Fixing Holes and Boundary Edges: Every model was carefully inspected and any open edges were filled and sealed to create a watertight, solid object.

- Analyzing Wall Thickness: We ensured that all walls had the required thickness for the intended printing material, preventing thin-wall failures that are common in 3D Printing.

- Detecting Internal Faces: We systematically identified and removed any hidden internal faces or geometry that would confuse the slicer software and lead to a failed print.

- Optimized for Physical Output: The models were prepared with a focus on their final physical form. This included considering factors like overhangs and the need for support material. We optimized the designs to be as self-supporting as possible, reducing the need for post-processing and ensuring a higher-quality final print.

- Final Export & File Delivery: The final step was to export a clean, error-free

.STLfile, the industry standard for 3D Printing. The client received a file that was ready to be imported directly into their slicer software, saving them valuable time and ensuring a successful print every time

The Impact: Elevated Design and Guaranteed Print Success

The client was exceptionally pleased with the Multiple 3D Models for Printing project. The guaranteed print success of each model provided immense value, eliminating the frustration and material waste of failed prints. The project stands as a prime example of our proficiency in delivering top-tier 3D modelling services, demonstrating a deep understanding of not only digital design but also the complex requirements of digital fabrication and manufacturing.

For more examples of our detailed product modelling and realistic visualization, be sure to explore our portfolio. You might find our work on the Loud Panda Vape particularly interesting for another perspective on creating high-quality, photorealistic product models with a focus on both intricate materials and a professional studio presentation. You can also find these assets, and many others, available for purchase or viewing on CGTrader.